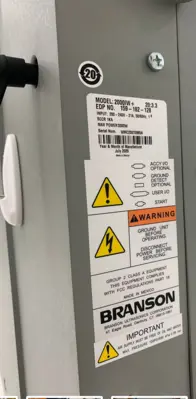

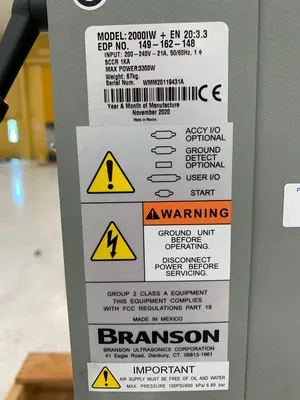

<p>Make: Branson<br/>Model: 2000IW<br/>Condition: Used, LIKE NEW - EXCELLENT SHAPE!!!<br/>7 units available - Multiple Available - See Last Picture<br/>4 units with amplitude control.<br/>3 units without amplitude control.<br/>Dimensions: 44.0in x 36.0in x 88.0in.<br/>Weight: 300 lbs<br/>New without any accessories, the cost was $18,500 each.<br/>Extras we purchased were leveling kits and factory installed amplitude controllers.</p>

<p>We used them for less than a year, welding thin layers of polypropylene fabric. They have always been stored in a clean, climate controlled environment and they look new.</p>

<p>Factory info from Branson Site:Specifications: Key Features<br/>• Line / Load Regulation - corrects for variations due to power line<br/>fluctuations and varying load conditions through Branson’s proprietary<br/>closed-loop amplitude control. Output amplitude is maintained with a<br/>variation of only + 2% with line voltage fluctuations of +10%, regardless<br/>of load. It ensures constant power in welding and provides greater weld<br/>consistency and reliability.<br/>• 2000 Series 20 kHz converter - produces 20% higher output amplitude than its 900 Series predecessor for faster weld cycles; in addition, this converter is more rugged and has higher power capacity.<br/>• Auto Seek - automatically measures stack frequency and stores it in memory. Three selectable Auto Seek choices are available:<br/>1. On power up, setting memory for the initial weld.<br/>2. Depressing “test” switch.<br/>3. By once/minute timer to track heating, cooling, and other effects.<br/>• Digital parameter entry with autoranging - when entering parameters<br/>gives precise settings for repeatable accuracy. The autoranged values enable fine resolution and setup accuracy.<br/>• A linear optical encoder - (IW+ models only) measures weld “distance.”<br/>The resolution on the encoder is 0.0001 inch (0.0025 mm).<br/>• Afterburst with variable delay and duration - is available to dislodge a part or material adhering to the horn face.<br/>• Individual select keys - allow easy selection of parameters to be modified.<br/>Active choice is lighted.<br/>• Sequence of operation - is displayed in the digital LED window during the welding cycle.<br/>• Self-diagnostics and cycle monitoring - features and capabilities provide fast, accurate troubleshooting and minimize downtime. During initial powerup, the unit completes a self-check and identifies any fault conditions or parameter errors before indicating that the system is “ready” for operation.<br/>• Visual and audible alarms, and external outputs - identify overload, machine faults and setup errors (e.g., emergency stop engaged).<br/>• Fast-response LED storage meter - displays power loading in 5% increments, and provides storage of the peak power achieved during the weld cycle as well as better visibility; 100% of rated output of the power supply is delivered at full meter reading.<br/>• Peak power reading - from the last welding cycle is available on the digital<br/>LED display by depressing the “reset” switch. Similarly, power in the tuning mode is digitally displayed when the “test” switch is depressed.<br/>• LED readouts display parameter settings - during setup and operation<br/>for easy reference and monitoring. LEDs are large and easy to read in most light conditions.<br/>• Lockout of front panel switches - is provided by and internal dip switch, preventing unauthorized parameter changes to the setup.</p><br/><br/><p><b>Key Features: </b></p>

<ul><li>Integrated Design - Combines Power Supply, controls, and welding stand, suitable for laboratory or lower volume production</li><li>Ease of Use - Designed for simplified setup, operation and portability </li><li>Digital Controls - Provides accurate and repeatable setups with features like line and load regulation and auto seek with memory </li><li><!--StartFragment-->Multiple Weld Modes: Supports welding by time, collapse distance, or absolute distance.<!--EndFragment--></li><li><!--StartFragment-->Special Functions: Includes Afterburst for dislodging parts, Automatic Pretriggering, and Dynamic Trigger Force.<!--EndFragment--></li><li><!--StartFragment-->Autotune Plus Memory: Automatically tunes and stores horn frequency.<!--EndFragment--></li><li>Convenient Features: "Pull-to-Set, Push-to-Lock," a calibrated flow control valve for downspeed accuracy, and a "Horn Down" key for setup.</li><li><!--StartFragment-->Ergonomic Design: Features a low-force palm button and built-in emergency stop.</li><li>Automation Interfacing: Can connect with external devices and controls.<!--StartFragment--><!--EndFragment--></li><li>Monitoring and Diagnostics: Provides visual and audible alarms and self-diagnostics for troubleshooting.<!--StartFragment--><!--EndFragment--></li><li>Robust Housing: Durable molded thermoplastic structural foam protects internal components.<!--StartFragment--><!--EndFragment--></li></ul><p><b>Specifications: </b></p><ul><li> Welding Frequency: 20 kHz</li><li>Welding Power: 3300 Watt</li><li>Voltage: <!--StartFragment-->120V/220V, 120-240V AC.<!--EndFragment--></li><li>Dynamic Trigger and Follow Through Range: 15 - 200 lbs </li><li>Weld and Hold time Range: 50 - milliseconds </li><li>Afterburst delay and duration: <!--StartFragment-->"Off" or 50-1,000 milliseconds<!--EndFragment--></li><li>Maximum Force on part: 630 lbs </li><li>Stroke Length: 3.9" / 100mm</li></ul>